Table of Contents Show

The ability to adapt and enhance operational efficiency is crucial for success. Organizations are constantly seeking ways to streamline their workflows, reduce waste, and improve overall performance.

This is where process improvement tools come into play. These tools and techniques are designed to help businesses analyze their existing processes, identify bottlenecks, and implement effective changes that lead to better outcomes.

Process improvement software has emerged as a vital resource for teams aiming to optimize their operations. By leveraging technology, businesses can gain valuable insights into their processes, enabling them to make data-driven decisions that foster growth and innovation.

Whether you are a small startup or a large corporation, understanding and utilizing the right process improvement tools can significantly enhance your operational capabilities.

In this article, we will explore the best process improvement tools and techniques available in 2024. From Lean Six Sigma to process mapping and automation, we will delve into various methodologies that can transform your approach to business processes.

Join us as we uncover the strategies that can lead to lasting improvements and a culture of continuous enhancement within your organization.

Getting To Know Process Improvement

Process improvement is a fundamental aspect of modern business practices, focusing on enhancing the efficiency and effectiveness of existing processes. This methodology involves a systematic approach to identifying, analyzing, and refining workflows to achieve better outcomes.

Definition of Process Improvement

At its core, process improvement refers to the practice of evaluating and enhancing existing business processes to make them faster, more accurate, and more reliable.

This ongoing endeavor aims to eliminate inefficiencies, reduce waste, and optimize performance across various operations.

Whether through minor adjustments or comprehensive redesigns, the goal is to create processes that align with organizational objectives and customer needs.

Benefits of Process Improvement

Implementing process improvement can yield numerous advantages for organizations:

- Enhanced Efficiency: Streamlining processes can significantly reduce the time required to complete tasks, allowing teams to focus on higher-value activities.

- Increased Productivity: By identifying and eliminating bottlenecks, businesses can improve output and overall productivity levels.

- Improved Quality: A structured approach to process improvement often leads to higher quality outcomes, as teams can focus on refining their work and adhering to best practices.

- Cost Reduction: Reducing waste and optimizing resource allocation can lead to substantial cost savings, enhancing the bottom line.

- Better Customer Satisfaction: Efficient processes contribute to faster service delivery and higher-quality products, ultimately leading to improved customer experiences.

- Greater Transparency: Process improvement fosters a culture of accountability, where team members understand their roles and responsibilities, facilitating better collaboration.

Key Principles of Process Improvement

By understanding and applying these principles, organizations can foster a culture of continuous improvement, ultimately leading to enhanced performance and competitive advantage.

These key principles underpin effective process improvement initiatives:

- Continuous Improvement: Emphasizing that process improvement is not a one-time effort but an ongoing commitment to enhance processes regularly.

- Data-Driven Decision Making: Utilizing data and metrics to identify problems, measure performance, and evaluate the impact of changes.

- Employee Involvement: Engaging team members at all levels to contribute insights and feedback, as they are often the best source of information about the processes they work with.

- Customer Focus: Keeping the end-user in mind ensures that improvements align with customer needs and expectations, leading to better satisfaction and loyalty.

- Holistic Approach: Considering the entire process rather than isolated components helps to identify interdependencies and optimize workflows more effectively.

Top Process Improvement Tools

Let’s dive in and learn about the best process improvement tools you need to be aware of:

1. Lean Six Sigma & DMAIC

Lean Six Sigma is a powerful methodology that combines two well-established process improvement techniques: Lean and Six Sigma.

This approach is widely recognized for its effectiveness in enhancing operational efficiency, reducing waste, and improving quality across various industries.

Lean focuses on eliminating waste within processes, ensuring that every activity adds value to the customer. It originated from the Toyota Production System and emphasizes principles such as continuous improvement and respect for people. On the other hand, Six Sigma is a data-driven approach that aims to reduce process variation and defects, thereby enhancing quality.

It was first introduced at Motorola in the late 1980s and has since evolved into a comprehensive framework for process improvement. When combined, Lean Six Sigma leverages the strengths of both methodologies to create a robust framework for improving business processes.

This synergy allows organizations to streamline operations, enhance customer satisfaction, and achieve significant cost savings.

DMAIC Methodology

The DMAIC framework is a cornerstone of the Lean Six Sigma approach. It consists of five phases:

- Define: Clearly articulate the problem, project goals, and customer requirements. This phase involves identifying the scope of the project and establishing a project team.

- Measure: Collect data to understand current process performance. This phase includes identifying key performance indicators (KPIs) and measuring the baseline performance of the process.

- Analyze: Examine the data to identify root causes of defects and variations. This phase involves using statistical tools to analyze data and pinpoint areas for improvement.

- Improve: Develop and implement solutions to address the identified root causes. This phase focuses on optimizing processes and eliminating waste while ensuring that improvements align with customer needs.

- Control: Establish controls to sustain the improvements made. This phase involves monitoring the process and implementing measures to ensure that gains are maintained over time.

By following the DMAIC methodology, organizations can systematically address process issues and achieve measurable improvements.

2. Kanban Method

Kanban is a popular visual management method that facilitates workflow optimization by enabling teams to visualize their processes, manage work in progress, and enhance overall efficiency.

Originating from Toyota’s production system, Kanban has evolved into a versatile tool used across various industries to improve productivity and streamline operations.

At its core, Kanban is a method for managing and improving work across human systems. It emphasizes visualizing the flow of work, allowing teams to see what is being worked on, what is completed, and what is pending.

The primary goal of Kanban is to enhance efficiency by limiting work in progress (WIP) and ensuring that tasks move smoothly through the workflow. Kanban operates on the principle of pulling work through the process rather than pushing it.

This means that new work items are only started when there is available capacity in the system, preventing bottlenecks and overloading team members. By visualizing the workflow and implementing WIP limits, teams can better manage their workload and focus on completing tasks effectively.

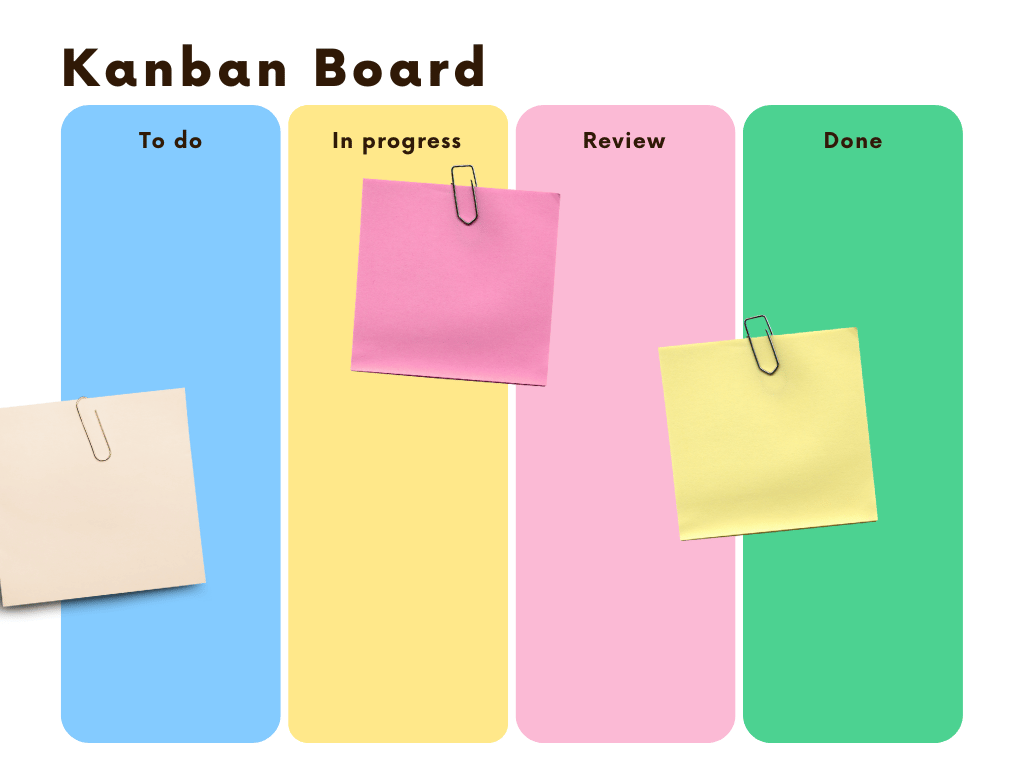

Kanban Board and Workflow Visualization

A Kanban board is a central component of the Kanban method, serving as a visual representation of the workflow. It typically consists of columns representing different stages of the process, with cards or sticky notes representing individual tasks.

As work progresses, these cards move from one column to another, providing a clear view of the status of each task. The visualization of workflow through a Kanban board offers several benefits:

- Transparency: Everyone on the team can see what tasks are in progress, who is working on them, and what remains to be done. This transparency fosters accountability and collaboration.

- Identification of Bottlenecks: By observing the flow of tasks on the board, teams can quickly identify stages where work is piling up, allowing for timely intervention to address issues.

- Improved Communication: The visual nature of the Kanban board enhances communication among team members, as it provides a shared understanding of the work being done.

To effectively implement a Kanban board, teams should start by mapping out their workflow, identifying key stages, and determining how to best represent tasks visually. This process often involves defining the scope of work and establishing clear criteria for moving tasks between columns.

3. Agile Methodology

Agile methodology is a revolutionary approach to project management that has transformed the way teams deliver products and services. Originating in the software development industry, Agile has been adopted by various sectors, becoming a powerful tool for driving continuous improvement and delivering value to customers.

At its core, Agile is an iterative and incremental framework that emphasizes collaboration, flexibility, and rapid delivery. It is a departure from traditional waterfall methodologies, which often struggle to adapt to changing requirements and market demands.

Agile breaks down projects into smaller, manageable chunks called sprints, each of which typically lasts one to four weeks. The Agile methodology is guided by four core values, as outlined in the Agile Manifesto:

- Individuals and interactions over processes and tools

- Working software over comprehensive documentation

- Customer collaboration over contract negotiation

- Responding to change by following a plan

These values emphasize the importance of people, collaboration, and adaptability in delivering successful projects.

Related:

Lean vs Agile: Unveiling Key Differences For Success

4. Business Process Modeling Notation (BPMN)

Business Process Modeling Notation (BPMN) is a standardized graphical method for representing business processes in a visual format.

It provides a clear and comprehensive way to model the steps involved in a business process, making it easier for stakeholders to understand and communicate these processes effectively.

BPMN has become an essential tool for organizations looking to improve efficiency, streamline operations, and enhance collaboration.

What is BPMN?

BPMN is designed to create a visual representation of business processes, enabling organizations to document, analyze, and improve their workflows.

The notation consists of a set of standardized symbols and rules that allow users to depict the sequence of activities, the flow of information, and the interactions between different participants in a process.

This visual approach helps bridge the gap between technical and non-technical stakeholders, facilitating better communication and understanding.

BPMN Elements and Notation

BPMN diagrams are constructed using four main categories of elements:

1. Flow Objects:

- Events: Represented by circles, events are triggers that initiate, modify, or complete a process. They can be categorized as Start, Intermediate, or End events, each serving different functions within the workflow.

- Activities: Depicted as rounded rectangles, activities represent tasks or work that needs to be performed. They can be simple tasks or complex sub-processes that encapsulate multiple tasks.

- Gateways: Shown as diamonds, gateways are decision points that control the flow of the process based on certain conditions. They determine which path the process will take, allowing for branching and parallel processing.

2. Connecting Objects:

- Sequence Flow: Illustrated as solid lines with arrows, sequence flows indicate the order in which activities are performed.

- Message Flow: Represented by dashed lines, message flows show the communication between different participants or processes.

- Association: Shown as dotted lines, associations link artifacts or data to flow objects, providing additional context.

3. Swimlanes:

- Pools: A pool is a large rectangle that represents a major participant in the process, such as an organization or department. It contains all relevant flow objects and connecting objects.

- Lanes: Lanes are subdivisions within a pool that categorize activities by role or function, clarifying who is responsible for each part of the process.

4. Artifacts:

- Data Objects: Indicate the data required for a specific activity.

- Groups: Used to group related activities without affecting the flow of the process.

- Annotations: Provide additional information or context to help clarify complex parts of the diagram.

Benefits of Using BPMN for Process Improvement

Utilizing BPMN offers several advantages for organizations seeking to enhance their business processes:

- Standardization: BPMN provides a common language for modeling processes, ensuring that all stakeholders can understand and interpret the diagrams consistently. This standardization is crucial for effective communication and collaboration across departments.

- Clarity and Visualization: The graphical nature of BPMN diagrams makes complex processes easier to understand. Visual representations help teams identify inefficiencies, redundancies, and bottlenecks that may not be apparent in textual descriptions.

- Enhanced Collaboration: By providing a clear visual model, BPMN fosters collaboration among team members, business analysts, and technical developers. This collaborative approach helps ensure that everyone is aligned on process goals and requirements.

- Improved Process Analysis: BPMN diagrams facilitate the analysis of existing processes, allowing organizations to identify areas for improvement. By modeling processes, teams can experiment with different scenarios and evaluate the potential impact of changes before implementation.

- Support for Automation: BPMN is compatible with various business process management (BPM) tools and software, enabling organizations to automate workflows based on the modeled processes. This automation can lead to increased efficiency and reduced manual effort.

- Continuous Improvement: BPMN encourages a culture of continuous improvement by providing a framework for regularly reviewing and refining processes. Organizations can use BPMN to document changes, track progress, and ensure that improvements are sustained over time.

5. Process Mapping

Process mapping is a powerful technique used to visualize the steps involved in a business process. It allows organizations to gain a clearer understanding of their workflows, identify inefficiencies, and implement improvements.

By providing a visual representation, process mapping enables teams to communicate effectively and align their efforts toward achieving common goals.

Definition of Process Mapping

Process mapping refers to the practice of creating a visual representation of a process, detailing each step, decision point, and interaction involved in completing a specific task or workflow. This technique helps organizations document their processes, analyze them for inefficiencies, and streamline operations.

By mapping out processes, teams can identify bottlenecks, redundancies, and areas for improvement, ultimately enhancing productivity and quality.

Process maps can take various forms, including flowcharts, swimlane diagrams, and value stream maps, each serving different purposes and providing unique insights into the workflow.

Types of Process Maps

There are several types of process maps, each suited for different analytical needs:

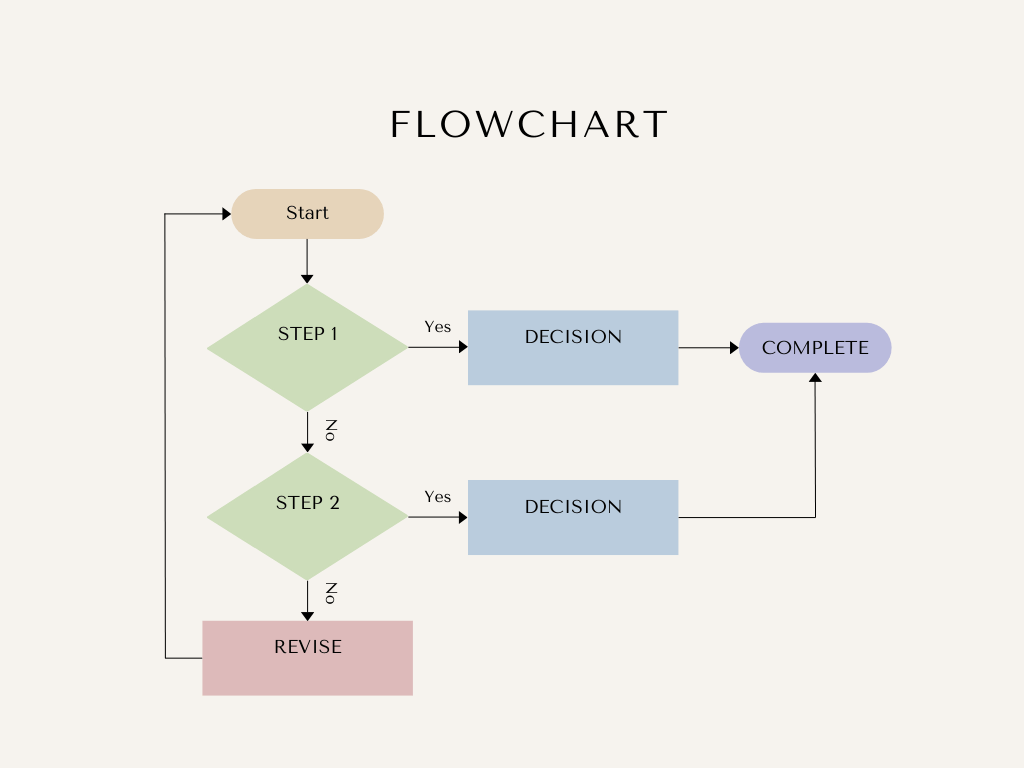

1. Flowchart:

A basic representation of a process that uses standardized symbols to illustrate the sequence of steps, decisions, and outcomes. Flowcharts are versatile and can be used for various processes, making them a popular choice for initial process mapping.

2. Swimlane Diagram:

This type of diagram organizes processes into lanes, each representing a different participant or department. Swimlane diagrams clarify responsibilities and interactions, making it easier to identify who is accountable for each step in the process.

3. Value Stream Map:

A lean management tool that visualizes the flow of materials and information throughout the production process. Value stream maps help identify waste and areas for improvement, focusing on maximizing value for the customer.

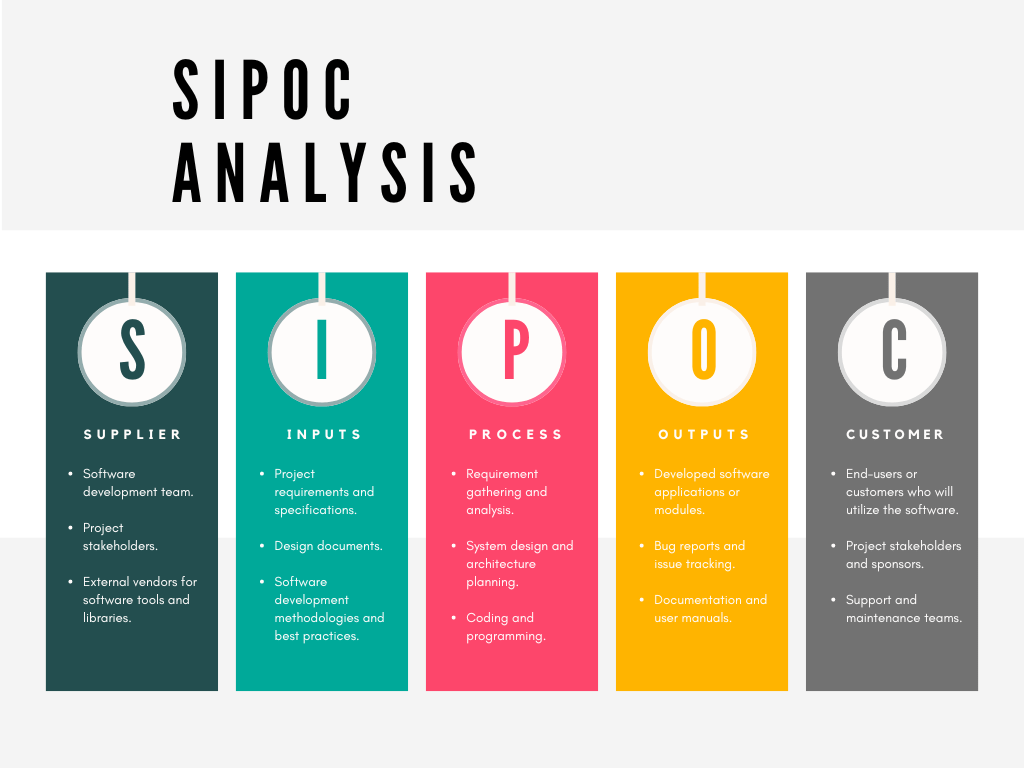

4. SIPOC Diagram:

An acronym for Suppliers, Inputs, Processes, Outputs, and Customers, this high-level process map provides an overview of the key elements of a process. SIPOC diagrams are useful for understanding the broader context of a process and identifying stakeholders.

5. Detailed Process Map:

This type of map provides an in-depth look at each step in a process, often including specific tasks, roles, and timelines. Detailed process maps are valuable for training and process documentation.

6. Document Map:

This map outlines the documents, inputs, and outputs associated with a process, helping teams understand the information flow and documentation requirements.

6. Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a systematic process used to identify the fundamental causes of problems or failures within an organization. By focusing on the root cause rather than just the symptoms, RCA helps organizations implement effective solutions that prevent recurrence.

This approach is essential in quality management and continuous improvement initiatives, as it enables teams to address issues at their source.

What is Root Cause Analysis (RCA)?

RCA is based on the premise that problems often have underlying causes that, if identified and addressed, can lead to more sustainable solutions. Instead of merely treating the symptoms of a problem, RCA seeks to understand why the problem occurred in the first place. This method is particularly valuable in complex systems where multiple factors may contribute to an issue.

The RCA process typically involves several steps:

- Define the Problem: Clearly articulate the issue that needs to be resolved.

- Collect Data: Gather relevant information and evidence related to the problem.

- Identify Possible Causes: Brainstorm potential root causes based on the collected data.

- Analyze Causes: Use various techniques to determine the most likely root causes.

- Implement Solutions: Develop and implement corrective actions to address the identified root causes.

- Monitor and Review: Evaluate the effectiveness of the solutions and make adjustments as necessary.

By following this structured approach, organizations can enhance their problem-solving capabilities and foster a culture of continuous improvement.

RCA Techniques

Several techniques can be employed during the RCA process, each offering unique advantages:

1. 5 Whys:

This technique involves asking “why” repeatedly (typically five times) to drill down to the root cause of a problem. Each answer forms the basis for the next question, helping to uncover deeper layers of the issue. It is particularly effective for straightforward problems where advanced statistical analysis is not required.

Example:

- Problem: The production line stopped.

- Why? The machine broke down.

- Why? A part failed.

- Why? The part was worn out.

- Why? It wasn’t replaced during maintenance.

- Why? The maintenance schedule was not followed.

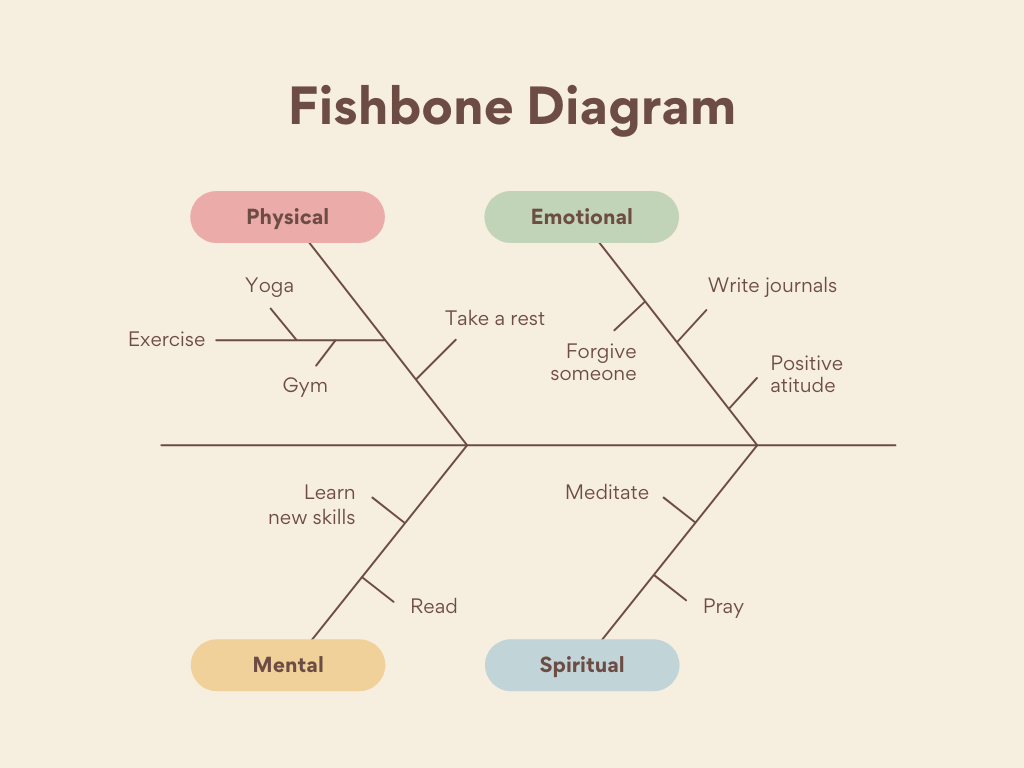

2. Fishbone Diagram (Ishikawa Diagram):

This visual tool helps categorize potential causes of a problem into different categories, such as people, processes, materials, and equipment. The diagram resembles a fishbone, with the problem at the head and the causes branching off. This method facilitates group discussions and helps teams organize their thoughts systematically.

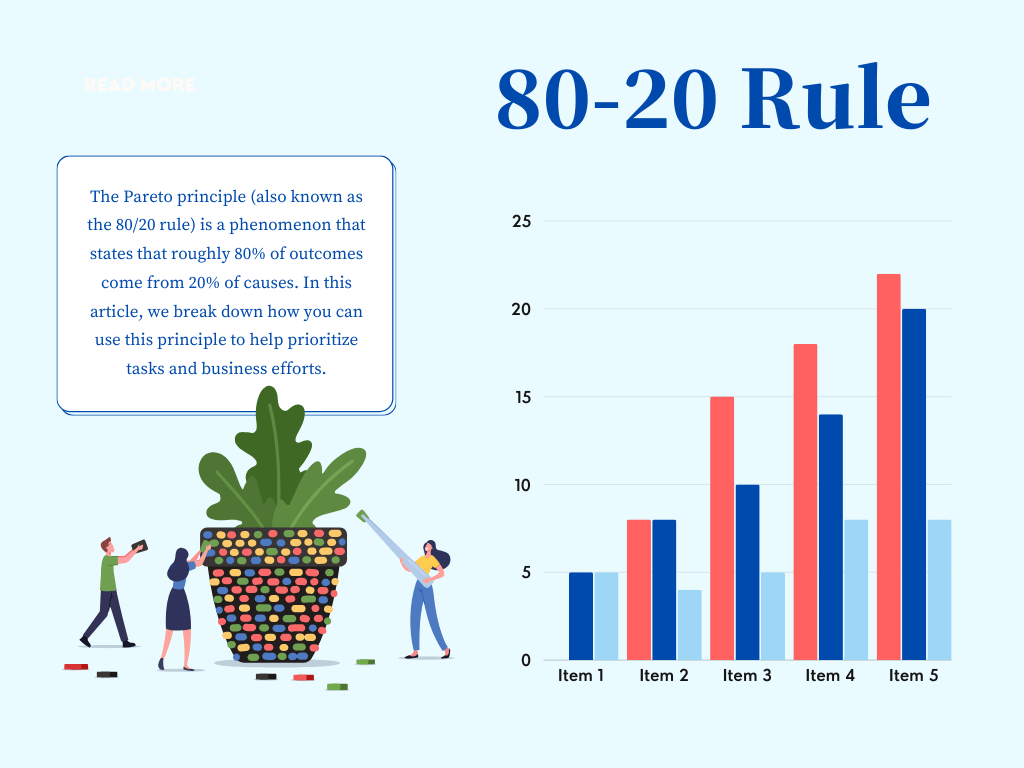

3. Pareto Chart:

Based on the Pareto Principle (80/20 rule), this chart helps identify the most significant factors contributing to a problem. By visually representing data in descending order, teams can focus their improvement efforts on the areas that will yield the greatest impact.

4. Failure Mode and Effects Analysis (FMEA):

This proactive approach assesses potential failure modes within a process and their consequences. By identifying and prioritizing risks, teams can implement preventive measures to mitigate potential issues before they occur.

5. Scatter Diagram:

This graphical representation plots two variables against each other to identify potential relationships. By analyzing the correlation between variables, teams can gain insights into factors that may be contributing to a problem.

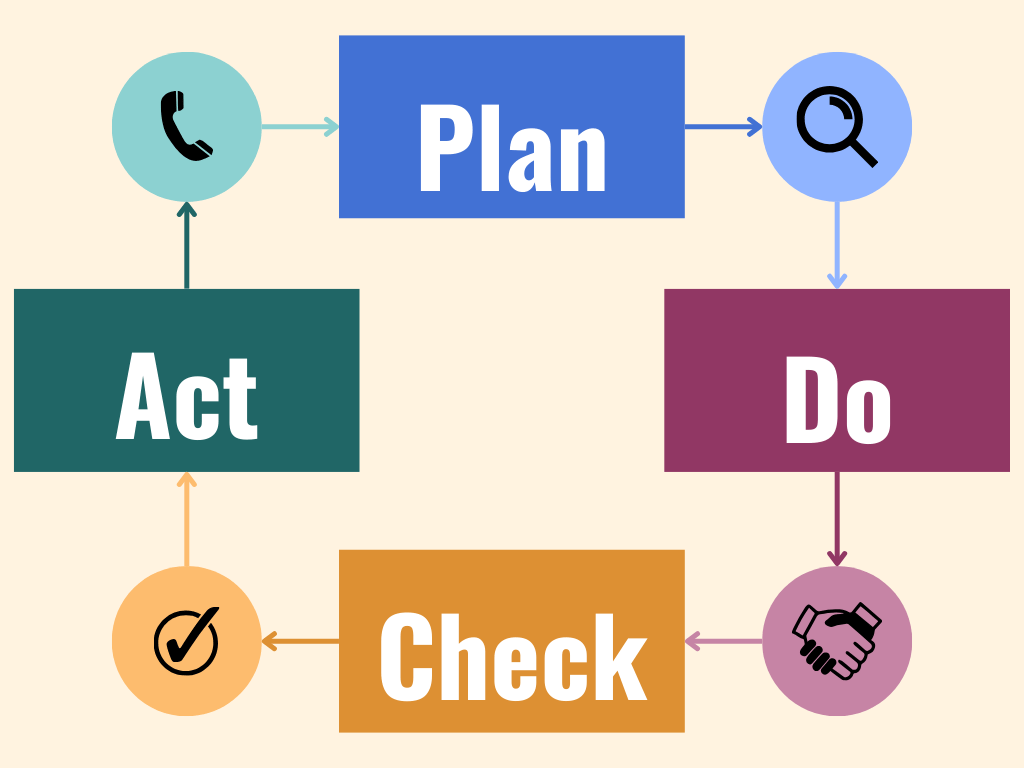

7. Continuous Improvement Cycle (PDCA)

The Continuous Improvement Cycle, commonly known as the PDCA cycle (Plan, Do, Check, Act), is a widely recognized framework that organizations use to foster continuous improvement in their processes, products, and services.

This iterative model provides a structured approach to problem-solving and process enhancement, enabling teams to implement changes effectively and sustainably.

Overview of the PDCA Cycle

The PDCA cycle consists of four key phases:

- Plan: In this initial phase, teams identify a specific problem or opportunity for improvement. They set clear objectives and develop a detailed plan outlining the steps necessary to achieve those goals. This may involve gathering data, analyzing current processes, and brainstorming potential solutions.

- Do: During the “Do” phase, the plan is executed on a small scale or in a controlled environment. This allows teams to implement the proposed changes while collecting data on the results. The focus here is on monitoring the implementation process and ensuring that all steps are followed as intended.

- Check: After the implementation, the “Check” phase involves evaluating the outcomes against the objectives set in the planning phase. Teams analyze the data collected during the “Do” phase to determine if the changes were effective and if the desired results were achieved. This step is crucial for identifying any discrepancies or unexpected issues.

- Act: Based on the findings from the “Check” phase, teams take appropriate actions. If the results were successful, the changes are standardized and integrated into regular operations. If further adjustments are needed, teams refine the plan and cycle back to the “Plan” phase. This iterative process encourages ongoing evaluation and continuous improvement.

The PDCA cycle is not only a tool for problem-solving but also a mindset that promotes a culture of continuous improvement within organizations. It is applicable across various sectors, including manufacturing, healthcare, and service industries, making it a versatile framework for enhancing operational efficiency.

Implementing PDCA for Continuous Improvement

To effectively implement the PDCA cycle, organizations should follow these steps:

- Engage Stakeholders: Involve team members and stakeholders in the planning phase to ensure diverse perspectives and insights are considered. This collaborative approach fosters buy-in and commitment to the improvement process.

- Set Clear Objectives: Establish specific, measurable, achievable, relevant, and time-bound (SMART) goals for the improvement initiative. Clear objectives provide direction and help teams focus their efforts.

- Develop a Detailed Plan: Outline the steps required to achieve the objectives, including timelines, resources, and responsibilities. A well-structured plan serves as a roadmap for implementation.

- Monitor Progress: During the “Do” phase, continuously monitor the implementation process. Collect data and feedback to assess how well the plan is being executed and identify any challenges that arise.

- Analyze Results: In the “Check” phase, analyze the data collected to evaluate the effectiveness of the changes. Compare the outcomes against the established objectives to determine if the desired improvements were achieved.

- Standardize Successful Changes: If the results are positive, take steps to standardize the successful changes. Document the new processes and integrate them into the organization’s standard operating procedures.

- Encourage a Culture of Continuous Improvement: Promote an organizational culture that embraces continuous improvement. Encourage employees to identify opportunities for enhancement and participate in the PDCA cycle regularly.

8. Process Automation: A Key Tool for Process Improvement

Process automation has emerged as a critical component of modern business operations, enabling organizations to streamline workflows, enhance efficiency, and drive continuous improvement.

By leveraging technology to automate repetitive, rule-based tasks, companies can free up valuable resources, reduce errors, and improve overall productivity.

Importance of Process Automation

In today’s fast-paced business environment, organizations are constantly seeking ways to optimize their processes and stay ahead of the competition. Process automation plays a vital role in this pursuit by:

- Increasing Efficiency: Automated processes can execute tasks faster and more consistently than manual methods, leading to significant time savings and improved productivity

- Reducing Costs: By eliminating the need for manual intervention in certain tasks, process automation helps organizations reduce operational costs and improve profitability

- Enhancing Accuracy: Automated systems are less prone to errors compared to manual processes, ensuring higher-quality outputs and reducing the risk of costly mistakes

- Improving Scalability: Process automation enables organizations to handle fluctuations in workload without compromising quality or speed, making it easier to adapt to changing business needs

- Fostering Agility: Automated systems can be quickly reconfigured to accommodate new requirements or integrate with emerging technologies, allowing businesses to respond more effectively to market changes

Examples of Process Automation Tools

There are numerous tools and technologies available to help organizations automate their processes, each offering unique features and capabilities:

- Robotic Process Automation (RPA): RPA software uses “bots” to mimic human actions and perform repetitive, rule-based tasks across multiple applications

- Business Process Management (BPM) Software: BPM tools help organizations model, automate, and optimize their business processes, often incorporating workflow management and analytics capabilities

- Enterprise Resource Planning (ERP) Systems: ERP software integrates various business functions, such as accounting, HR, and supply chain management, into a single system, enabling data sharing and process automation

- Workflow Management Systems: These tools help organizations define, execute, and monitor the flow of tasks and information within a process, ensuring that work is completed efficiently and consistently

- Intelligent Document Processing (IDP): IDP solutions use machine learning and natural language processing to automate the extraction, classification, and processing of data from various types of documents

9. Process Mining

Process mining is an innovative technique that leverages data analysis to gain insights into business processes. By extracting knowledge from event logs generated by information systems, organizations can visualize, analyze, and optimize their workflows.

This data-driven approach enables businesses to identify inefficiencies, bottlenecks, and compliance issues, ultimately leading to improved operational performance.

Introduction to Process Mining

Process mining combines data science and process management to provide a comprehensive view of how processes are executed within an organization. It allows businesses to understand their actual processes by analyzing event logs from various systems, such as ERP, CRM, and workflow management tools. By visualizing the flow of activities, organizations can identify discrepancies between the intended process and the actual execution. The primary goals of process mining include:

- Discovery: Uncovering the actual process flow based on real data, which can differ significantly from documented processes.

- Conformance Checking: Comparing the discovered process with predefined models to identify deviations and compliance issues.

- Enhancement: Suggesting improvements to optimize processes based on insights gained from data analysis.

By employing process mining, organizations can make informed decisions that lead to more efficient and effective operations.

Process Mining Techniques and Tools

Several techniques and tools are available for implementing process mining, each offering unique capabilities to analyze and optimize processes:

1. Process Discovery:

This technique involves creating a visual representation of the actual process flow from event logs. Tools like ProM and Celonis can automatically generate process maps that highlight the sequence of activities, decision points, and variations.

2. Conformance Checking:

This technique assesses whether the actual process adheres to predefined models or standards. Tools such as Apromore and Disco allow organizations to compare the discovered process with the intended process to identify deviations and compliance issues.

3. Performance Analysis:

This technique focuses on evaluating the performance of processes by analyzing key performance indicators (KPIs) such as cycle time, throughput, and resource utilization. Tools like QPR Process Analyzer and Signavio provide dashboards and analytics to monitor process performance.

Also, see:

12 Best OKR Software For Succesful Goal Management

4. Root Cause Analysis:

Process mining can also be used to identify the root causes of inefficiencies or problems within a process. By analyzing event logs, organizations can trace back to the factors contributing to delays or errors.

5. Predictive Analytics:

Some advanced process mining tools incorporate machine learning algorithms to predict future process behavior based on historical data. This capability allows organizations to anticipate issues and proactively implement improvements.

10. Benchmarking

Benchmarking is a systematic process of comparing an organization’s processes, performance metrics, and practices against those of industry leaders or best-in-class organizations.

This practice helps organizations identify areas for improvement, set performance standards, and develop strategies to enhance their operations. By understanding how they measure up against competitors and industry standards, businesses can adopt best practices that lead to improved efficiency, effectiveness, and overall performance.

Definition of Benchmarking

Benchmarking involves evaluating various aspects of business performance, including processes, products, and services, against established standards or best practices. The primary goal is to determine gaps in performance and identify opportunities for improvement.

This process can be applied to various functions within an organization, such as manufacturing, customer service, and supply chain management. Benchmarking can be a one-time event or part of a continuous improvement strategy.

Organizations often use benchmarking to assess their performance regularly, ensuring they remain competitive and responsive to industry changes.

Types of Benchmarking

There are several types of benchmarking, each serving different purposes and offering unique insights:

- Competitive Benchmarking: This type involves comparing an organization’s performance metrics and processes directly with those of its competitors. By analyzing competitors’ strengths and weaknesses, organizations can identify areas where they can improve and differentiate themselves in the market.

- Functional Benchmarking: In this approach, organizations compare their processes and performance metrics with those of similar functions in different industries. This broader perspective allows companies to adopt innovative practices that may not be prevalent in their own sector.

- Internal Benchmarking: This type involves comparing performance metrics and processes within different departments or divisions of the same organization. Internal benchmarking helps identify best practices within the organization and promotes knowledge sharing among teams.

- Generic Benchmarking: This approach focuses on comparing processes or practices that are similar regardless of the industry. Organizations can learn from best-in-class practices in unrelated fields to drive innovation and improvement.

- Process Benchmarking: This type emphasizes comparing specific processes across organizations to identify best practices and performance metrics. It focuses on understanding how top-performing organizations achieve superior results in particular processes.

Steps to Conduct Effective Benchmarking

To conduct effective benchmarking, organizations should follow these structured steps:

- Identify the Area for Benchmarking: Determine which processes, functions, or performance metrics will be the focus of the benchmarking effort. This decision should align with organizational goals and areas identified for improvement.

- Define Objectives and Scope: Clearly outline the objectives of the benchmarking initiative. Establish the scope of the benchmarking effort, including the specific metrics to be compared and the organizations that will be included in the analysis.

- Select Benchmarking Partners: Identify organizations that excel in the area being benchmarked. These can be direct competitors, industry leaders, or organizations from different sectors with exemplary practices.

- Collect Data: Gather quantitative and qualitative data on the selected metrics from both the organization and the benchmarking partners. This may involve surveys, interviews, industry reports, and performance metrics.

- Analyze Data: Compare the collected data to identify performance gaps and best practices. Analyze the reasons behind the differences in performance and determine what can be learned from the benchmarking partners.

- Develop Action Plans: Based on the analysis, create actionable plans to implement the identified best practices and improve performance. This may involve process redesign, training, or resource allocation.

- Implement Changes: Execute the action plans, ensuring that all stakeholders are engaged in the process. Communicate the changes clearly and provide the necessary training and resources to support implementation.

- Monitor and Review: Continuously monitor the results of the changes made and assess their impact on performance. Regularly review the benchmarking process to ensure it remains relevant and effective.

- Foster a Culture of Continuous Improvement: Encourage ongoing benchmarking as part of the organization’s culture. Promote knowledge sharing and collaboration among teams to sustain improvements and adapt to changing market conditions.

By effectively conducting benchmarking, organizations can gain valuable insights into their performance, identify best practices, and implement strategies that drive continuous improvement. This proactive approach not only enhances operational efficiency but also positions organizations for long-term success in a competitive landscape.

11. Total Quality Management: A Holistic Approach to Process Improvement

Total Quality Management (TQM) is a comprehensive and structured approach to organizational management that seeks to improve the quality of products and services through ongoing refinements in response to continuous feedback.

Developed in the 1950s by quality management pioneers like W. Edwards Deming and Joseph Juran, TQM has evolved into a widely adopted methodology for process improvement across various industries.

Key Principles of TQM

TQM is built upon several core principles that guide organizations in their pursuit of quality and continuous improvement:

- Customer Focus: Understanding and meeting customer requirements is the primary focus of TQM. Organizations must strive to exceed customer expectations and deliver value.

- Employee Involvement: All employees, from top management to frontline workers, must be engaged in the quality improvement process. TQM relies on the collective knowledge and skills of the workforce.

- Process-Centered: Improving processes is essential to enhancing products and services. TQM emphasizes the importance of managing and improving key processes throughout the organization.

- Integrated System: TQM views the organization as an integrated system, with each part contributing to the whole. Departments and functions must work together to achieve common goals.

- Strategic and Systematic Approach: Quality improvement must be planned, implemented, and measured using a systematic approach. TQM requires a long-term commitment and strategic alignment with organizational objectives.

- Continuous Improvement: Improving quality is an ongoing process. TQM encourages organizations to continuously evaluate and enhance their processes, products, and services.

- Fact-Based Decision Making: Effective decision-making relies on the analysis of data and information. TQM emphasizes the importance of collecting and using accurate data to drive improvement efforts.

TQM Tools and Techniques

TQM employs a variety of tools and techniques to support the quality improvement process. Some of the most commonly used tools include:

- Seven Basic Quality Tools: These tools, also known as the “Seven QC Tools,” are used for data collection and analysis. They include cause-and-effect diagrams, check sheets, control charts, histograms, Pareto charts, scatter diagrams, and flow charts.

- Seven New Management Tools: These tools help organizations plan and implement quality improvement projects. They include affinity diagrams, relations diagrams, tree diagrams, matrix diagrams, matrix data analysis, process decision program charts, and activity network diagrams.

- Quality Function Deployment (QFD): QFD is a structured approach for translating customer requirements into technical specifications and production/process requirements.

- Failure Mode and Effects Analysis (FMEA): FMEA is a proactive tool used to identify potential failures in products or processes and prioritize corrective actions based on risk.

- Statistical Process Control (SPC): SPC involves the use of statistical techniques to monitor and control a process, ensuring that it operates at its full potential.

Implementing TQM

Successful implementation of TQM requires a comprehensive and systematic approach. Key steps in the implementation process include:

- Gaining Top Management Commitment: Securing the support and involvement of top management is critical to the success of TQM initiatives.

- Establishing a Quality Council: A quality council, composed of representatives from various departments, oversees the TQM implementation process and coordinates improvement efforts.

- Providing Training: Employees at all levels must receive training in quality principles, tools, and techniques to support the TQM implementation.

- Communicating the TQM Vision: A clear and compelling vision for quality improvement must be communicated throughout the organization to create a shared understanding and commitment.

- Measuring Progress: Establishing performance measures and monitoring progress is essential to ensuring the effectiveness of TQM initiatives and identifying areas for further improvement.

By embracing the principles and tools of TQM, organizations can create a culture of quality, foster continuous improvement, and deliver superior products and services to their customers. As a comprehensive and holistic approach to process improvement, TQM remains a powerful tool for organizations seeking to enhance their competitiveness and long-term success.

As It Turns Out:

Throughout this exploration of key tools and techniques, it is clear that each method offers unique insights and strategies for enhancing operational efficiency and effectiveness.

Additionally, the increasing emphasis on sustainability and ethical practices will drive businesses to refine their processes not only for efficiency but also for environmental and social responsibility.

As organizations continue to navigate the complexities of an ever-evolving marketplace, leveraging these process improvement tools and techniques will be essential for achieving lasting success.

By committing to continuous improvement and staying attuned to future trends, businesses can enhance their performance, deliver exceptional value to customers, and thrive in a competitive environment.

Handpicked Readings For You:

1 comment